Carbon: Introductionwith permission, based on Ian M. Watt’s book1 and article4

|

|

|

Carbon films are uniformly amorphous and highly transparent to electrons because carbon has a low atomic weight. Due to their strongly interconnected three-dimensional network structure, carbon films have remarkable mechanical stability, even when as thin as 1 - 2nm3. References: |

|

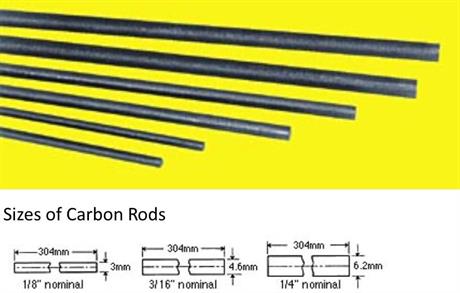

Carbon Rods

|

The carbon rods are offered in either spectroscopically pure or technical grades for standard electron microscopy evaporation requirements using carbon coaters. Due to the purification process used all carbon rods we supply have a graphite structure. The purification process removes impurities at a high temperature and causes the carbon to crystallize. The graphite structure has no adverse effects on the carbon coating or the carbon coating process. The user might perceive an additional advantage: the carbon rods (graphite rods) are less brittle than the carbon rods and are easier to handle and easier to shape. |

|

Technical grade carbon rods have a typical impurity level of around 50ppm or greater. Typical applications are non critical SEM or SEM/EDS coating of non-conducting samples. |

Grade 1 Spec-Pure Carbon Rods

Spectroscopically pure graphite structure carbon rods with an impurity level of 2ppm or less with 1ppm as maximum level for each element. Trace elements can be Si, Al, Fe, Mg, Ca or B (less than or equal to 1ppm). The rods are all 12" long with three nominal diameters (1/8", 3/16" and 1/4") to comply with the carbon source used in different high vacuum carbon evaporators. Highly recommended for TEM, FESEM, FIB, WDS, EBSD, Microprobe and more critical SEM/EDS applications. Density 1.10 g/cm³, resistivity 67 µΩm, hardness 32 shore, and porosity 29%.

"CARBON ROD, GR 1, 1/4"" PK/12"

Carbon Rods, Grade 1 Spec-Pure, 1/4" x 12" (6.2 x 304mm)

"CARBON ROD,GR 1, 1/8"" PK/12"

Carbon Rods, Grade 1 Spec-Pure, 1/8" x 12" (3 x 304mm)

"CARBON ROD,GR 1, 3/16"" PK/12"

Carbon Rods, Grade 1 Spec-Pure, 3/16" x 12" (4.6 x304mm)

Frequency Specific High Purity Carbon Rods for Cressington Carbon Coaters. Impurity level of 5ppm or less.